Automated specialized equipment for glass and ceramic materials

Privacy warning

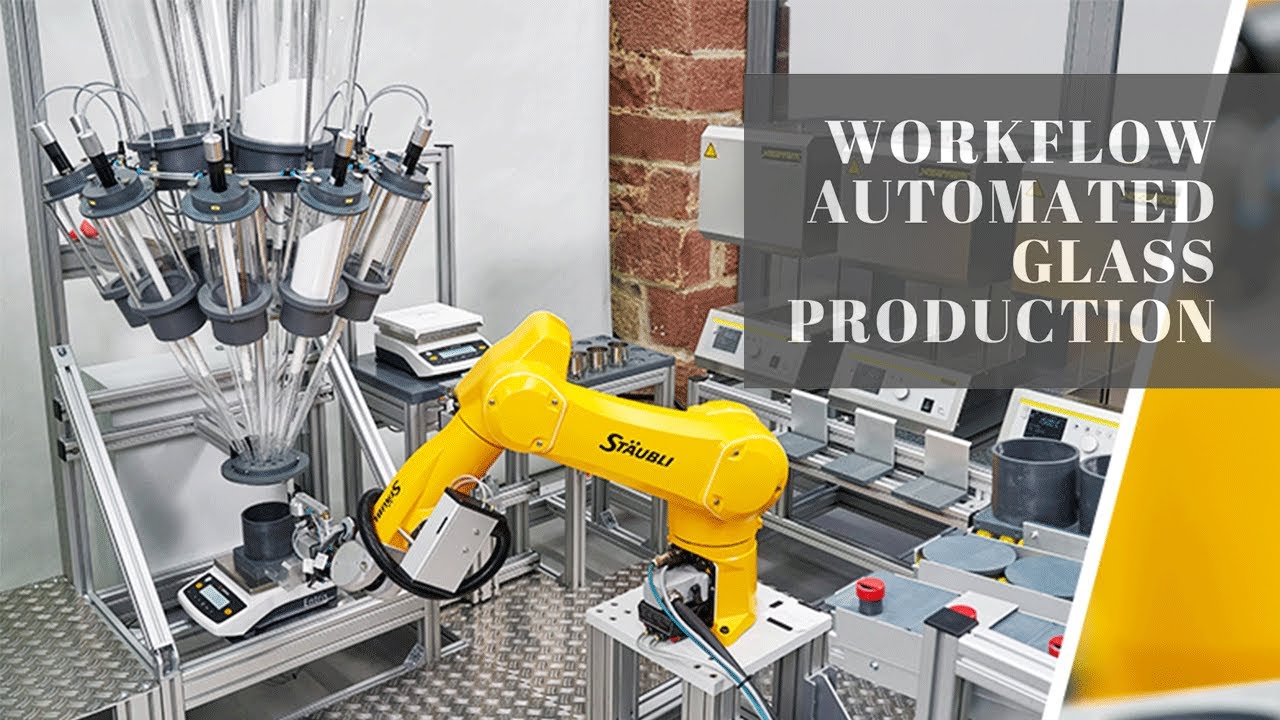

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyAutomated system for the production of new specialty glasses

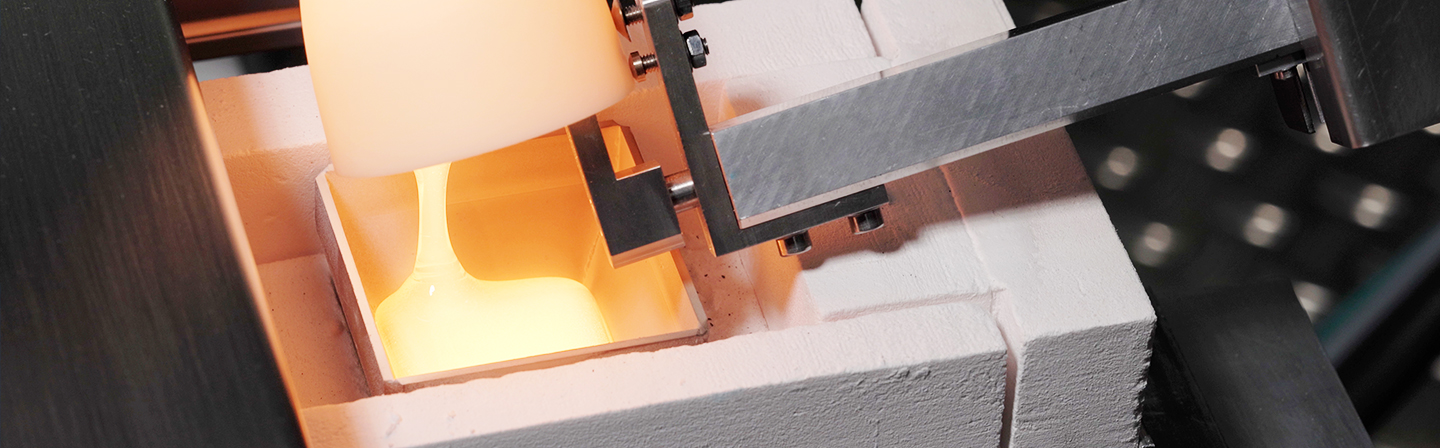

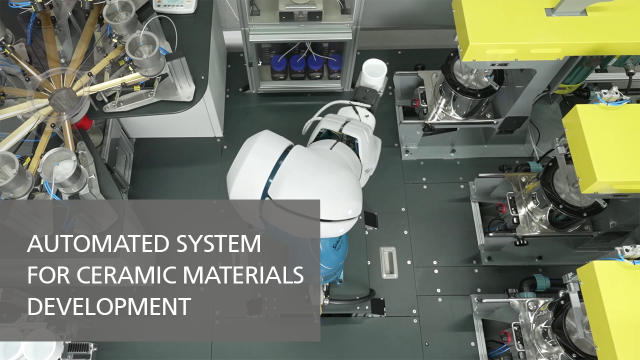

The Center of Device Development CeDeD designs and manufactures automated specialized equipment and systems for key tasks in materials research and development. Our custom-built systems support companies and research institutions in reliably producing complex functional materials and in evaluating new material compositions more quickly. The focus lies on precise raw material handling, clearly defined and reproducible process steps, and end-to-end data acquisition. This enables faster development of new materials, targeted optimization of existing formulations, and efficient scaling of production processes. Central application areas include automated glass development and the production of ceramic materials.