Precise optical measurements: Non-contact and under controlled conditions up to 2,400 °C / 4,352 °F

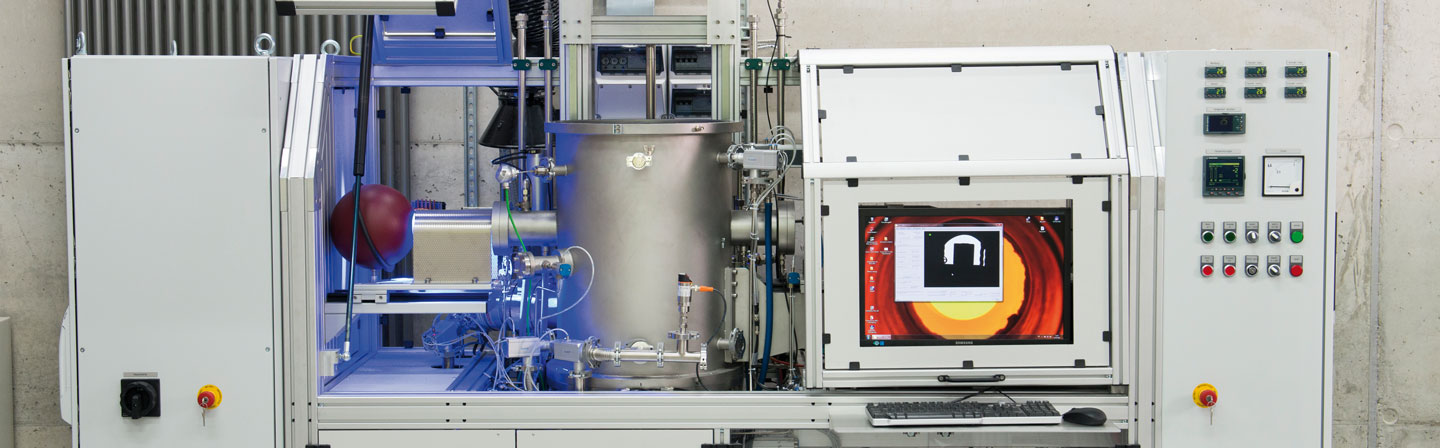

The Center of Device Development CeDeD at Fraunhofer ISC develops and manufactures custom high-temperature measurement systems and high-precision thermal testing equipment for in-situ material characterization under extreme temperatures, controlled atmospheres, and customizable environmental conditions.

Our optical high-temperature testing systems (Thermo-optical measuring systems: TOM units) are tailored to specific customer requirements and application scenarios. They enable the realistic simulation of industrial thermal treatment processes on a laboratory scale across a wide temperature range from -40 °C to +2,400 °C (-40 °F to + 4,352 °F).

The systems allow non-contact and largely non-destructive testing of materials under defined and reproducible conditions. They are applied across various industries such as energy technology, aerospace, process engineering, and advanced materials research.

Material characterization of high-temperature materials and components

The TOM systems measure key thermal and mechanical properties of a wide range of materials including ceramics, glass, metals, and refractory materials; both bulk and porous materials as well as fibers. Key testing capabilities include:

- Thermal expansion, dimensional change, swelling, and bending behavior

- Sintering behavior

- Weight loss and thermal decomposition

- Viscosity and softening temperatures (e.g. in glass melts)

- Creep behavior

- Elastic modulus (Young’s modulus)

- Thermal conductivity

- Wetting behavior

- Climate stability

- Surface characterization

Measurements under realistic conditions: From -40 °C to +2,400 °C (-40 °F to + 4,352 °F)

Our measurement systems operate under controlled temperature and environmental conditions. Depending on the application, they enable testing:

- in climate chambers from -40 °C to +180 °C (-40 °F to + 356 °F)

- and in high-temperature environments up to +2,400 °C / 4,352 °F

- under specific atmospheres (e.g., vacuum, gases, pure hydrogen, etc.)

- at defined humidity levels

Real-time optical monitoring during heating and cooling phases enables high-resolution analysis of deformation, melting behavior, and microstructural changes in materials.

Custom Testing Systems for Research and Industry

The systems developed at CeDeD combine various heating methods, vacuum technology, laser technology, and robotics into modular high-temperature testing platforms with a high degree of automation. They support both research institutions and industrial customers in quality assurance, process optimization, material characterization, and materials development.

Expandable with additional modules

Our measurement systems offer flexible expandability. Successfully integrated modules include:

- Gas analysis using mass spectrometry or IR spectroscopy

- Thermogravimetric analysis

- Application of mechanical loads up to 5000 N

- Ultrasonic crack detection

- Thermal shock via laser pulses

- Dynamics of metal droplet formation captured with high-speed cameras