Center of Device Development CeDeD –

Special Device Engineering by Fraunhofer ISC

We develop and build highly specialized measurement and testing systems for research and industry – from initial concept to full-scale series integration.

The Center of Device Development CeDeD at Fraunhofer ISC specializes in the design, development, and construction of scientific instruments and research facilities tailored to individual customer requirements. A particular focus lies on systems for material characterization, analysis, and the development of new materials, on measurement and testing systems for quality control in production processes, and on automated adjustment devices for laboratory glassware.

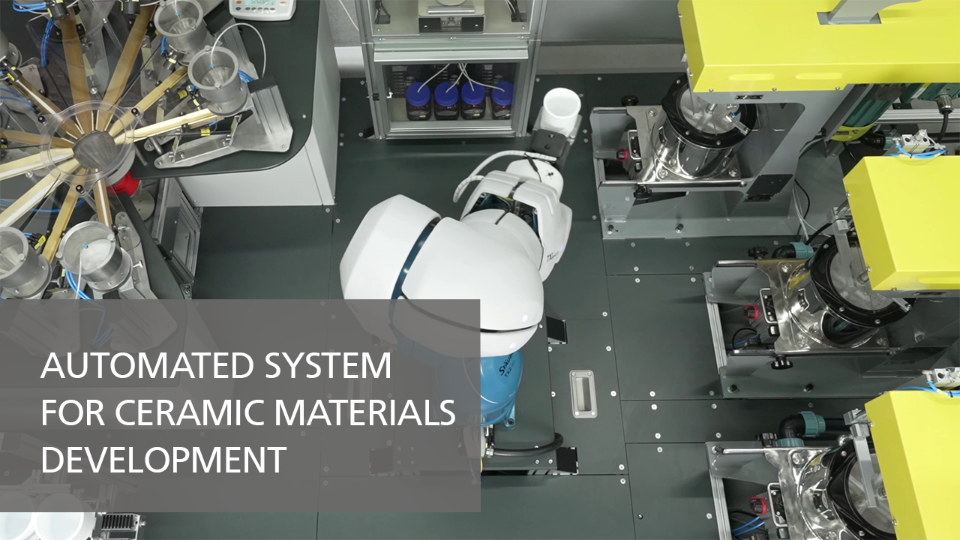

At the Bronnbach site, CeDeD combines scientific development expertise with industrial precision. Its service portfolio covers the entire development process, from the concept and design phase using advanced 3D modeling to engineering, design, and computer-aided manufacturing in its in-house production facilities. As a central point of contact for research groups and industry partners, CeDeD produces prototypes, demonstrators, and pilot plants for the production, processing, and testing of innovative materials. This also includes research instruments for process control and systems that can be directly integrated into industrial production lines.

High-Temperature Measurement Systems and In-Situ Material Characterization

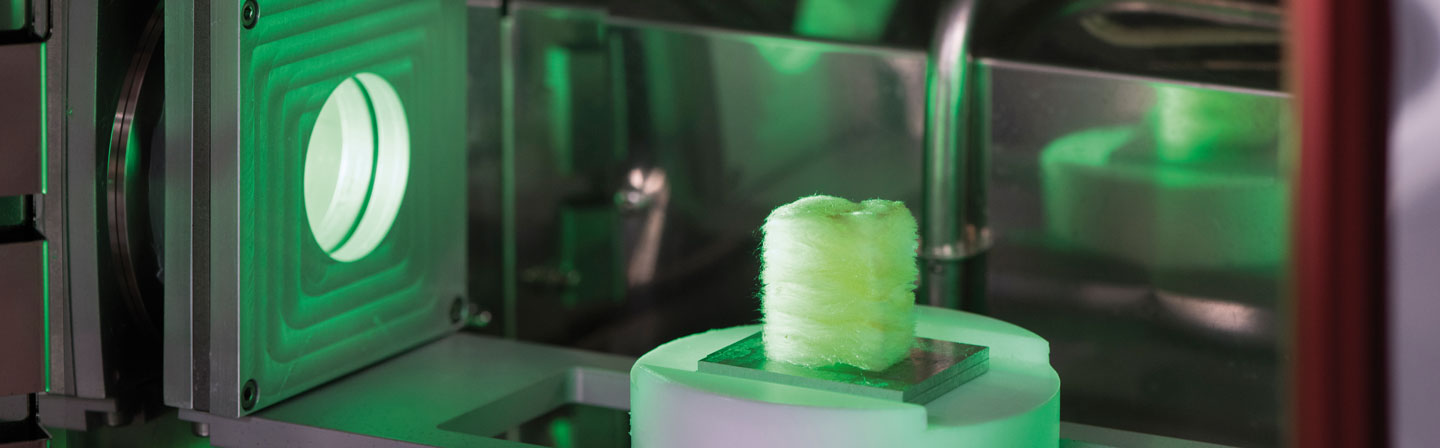

A core competence of CeDeD is the development of high-temperature measurement systems (thermo-optical measurement systems) for the in-situ characterization of materials during thermal processes. These optical measurement systems enable precise material analysis under real heat treatment conditions, ranging from room temperature up to over 2,400 °C / 4,352 °F.

The innovative CeDeD technologies are applied in the specialty glass industry, high-tech ceramics production, and the development of refractory materials. By employing state-of-the-art vacuum technology, laser systems, and robotics, highly automated systems are created for scalable industrial applications. The developed thermo-optical measurement methods are ideally suited for materials that undergo heat treatment during production, such as in powder metallurgy, injection molding, or high-performance material development. CeDeD thus provides tailored, reproducible, and efficient solutions for high-temperature material characterization in both research and industry.

Certified Quality and Reliability

CeDeD is ISO 9001:2015 certified, ensuring a fully traceable and reproducible process chain. With annual quality management audits, CeDeD stands for maximum reliability, technical excellence, and innovation, serving as a strong partner for companies and research institutions developing new technologies and implementing precise measurement solutions.