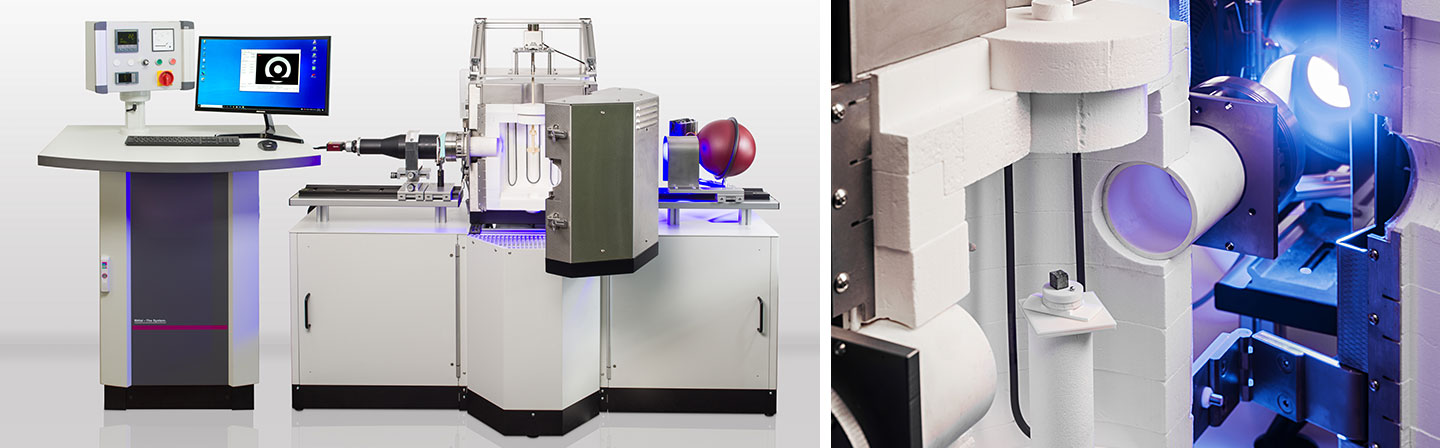

Measurements on ceramics

Ceramics are densified and strengthened by sintering. This process controls the quality of the final product – and considerably contributes to production costs. The sintering shrinkage is the most telling indicator for the sintering state. Close monitoring of shrinkage and warping during firing can be used to optimize firing conditions.

Our task

- Monitoring of the sintering shrinkage without mechanical impact of the measuring device on the samples

- Recording of any warping or adherence of the sample during sintering even if the sample shape is quite irregular

- Measuring of creep properties under well defined constant or cyclic loads.

Measurements on glass

Glass is molten and shaped at low viscosities. Numerous thermophysical data are required on the way from the raw material to the melt to ensure the precise design of the thermal processes. The measuring of thermophysical properties of glass around the softening temperature is particularly difficult.

Our task

- Determination of the expansion coefficient in the range from low temperature to melting temperature, i. e. around the softening temperature

- Monitoring of the melting behavior as well as the wetting of refractories and metallic molds by the glass melt at high temperatures